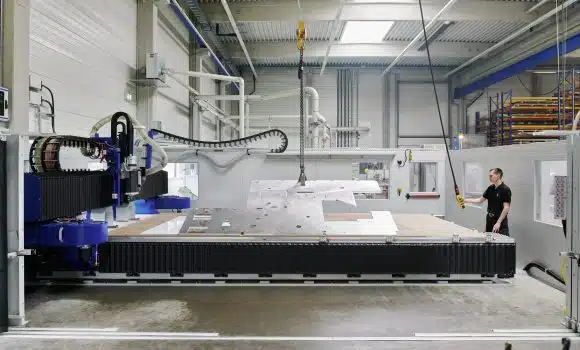

NOVA is Belotti’s Series CNC centres developed for cutting and milling large-sized parts in aluminium first, but also reinforced, technical plastics and composite materials such as carbon fiber and Kevlar. Starting from single or multi-layer sheets of these materials, a Belotti NOVA is able to meet the latest challenges of the international markets, especially for mechanical engineering, but also aerospace, packaging and some other niche applications. The requirements can be very varied, so this new Belotti solution guarantees extreme flexibility and reliability as well as high precision, especially in finishing processes, and efficiency. Representing the most advanced, technologically-powered version of a traditional pantograph, this machining center works large-sized pieces of different thicknesses down to the smallest detail, so assuring excellent results in terms of accuracy and usability, such as a greater operational simplicity.

Batz & Burgel has been specialising in the processing of aluminium sheets for more than 30 years and can produce aluminium components of different size and thickness, worked into detail and delivered already assembled for mechanical engineering. B+B has been able to meet the main trend of the market, implementing its own innovations and expanding its productivity thanks to the new Belotti NOVA. Currently, it is able to supply very large machined plates, also putting its engineering know-how at the service of their customers. The know-how acquired in practice grows with experience and thanks to the cooperation between customer and supplier. In this context, the relationship between Belotti and Batz & Burgel is very important for the further development of both companies on the German market.

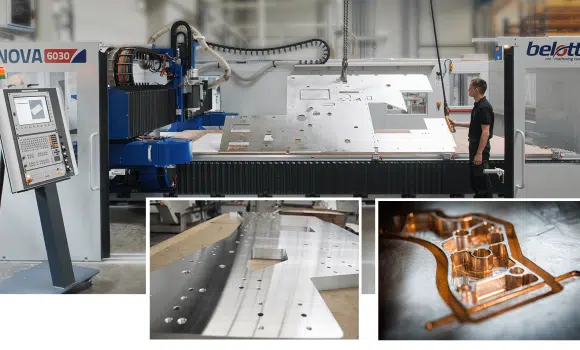

NOVA 6030 S is the solution chosen by B+B to increase productivity and to extend the processing variety to ever larger panels.

“We were looking for an even more flexible solution compared to the existing CNC machines” – says Mr. Batz – “We wanted a CNC machining centre that could process parts with even greater thicknesses and dimensions beyond the existing possibilities. In our plant we saw aluminium plates with a maximum thickness of 300 mm; in this case, we needed a solution that could also guarantee higher precision even when machining these very large parts, thus meeting the growing demand of our customers. For these reasons, we got in touch with Belotti S.p.A.“.

NOVA 3060 S (S for double drive motors in the X-axis) can work panels up to a size of 3 x 6 m, with a thickness between 15 and 40 mm. This solution has been specifically developed with B+B and is equipped with a number of options to guarantee the high performances required by the customer: the selected milling spindle – IBag with spray cooling system for the tool, ensures the required cutting values as well as the highest surface quality; Heidenhain linear scales and direct encoders improve the repeatability and precision of the machine positioning; The Heidenhain CNC control represents a standardization and harmonization with the existing machining centers.

The main advantages that Batz & Burgel recognized immediately after the installation of the Belotti NOVA in the production cycle are speed, user-friendliness and production efficiency in line with requirements.

“Belotti NOVA 6030 S has been in operation since the beginning of 2019; we are improving daily and becoming more and more effective. If we look at our other machining centres with their workpiece clamping system, we see that the Belotti NOVA is certainly a faster and simpler solution thanks to its vacuum table“, concludes Jürgen Batz.

Read more about this solution: https://batz-burgel.com/en/aktuelles-en/new-special-milling-machine-for-large-format-machine-body-panels/