With the inauguration of the new Lavrio production site in 2021, TECHNOHULL®, the Greek builder of high-end boats and dinghies, has completed one of the largest investments ever made in the nautical sector in Greece and one of the most important internationally.

The site covers 50 acres of land with a 12.000 sq.m dedicated to a fully integrated vertical production, where high expertise and cutting-edge technology meet craftsmanship of the highest standard. The new facility will manage all the elements of the production process: from concept development, design and prototyping to final production, engineering and set-up.

The production site is now equipped with a highly efficient production plant ready to work at full capacity to build high performance luxury boats and has the most advanced infrastructure to ensure the highest quality of construction and guarantee the feasibility of the most ambitious projects.

Belotti played an active role in the realisation of this project through the supply of a giant machine: a Belotti NAVY 20062 5-axis machining center (20 m x 6,2 m Z-axis of 3.5000 mm) designed to satisfy all in-house prototyping processes.

“Investing in an in-house prototyping unit was part of Technohull®’s strategic plan to develop a fully integrated state-of-the-art production facility to support its endeavors” says Gerasimos Petratos, Technohull®’s CEO.

“Having done a thorough research, we chose Belotti Navy for its high-quality units, as well as for its responsiveness and premium after sales service reputation. Having a very close cooperation for a bit more than a year now, we are already exploring ways to further strengthen our cooperation, discussing about other advanced technoholy tools, like large scale 3D printing units and smaller multi axis machines, that are indispensable tools for any contemporary shipyard.”

Belotti NAVY Series CNC machining centers are designed to meet the requirements of shipyards. The wide range of models in terms of dimensions and configurations allows to process both the models and the final /structural parts of a medium-size boat: from cutting resin models up to trimming fiberglass hulls and other high resistance composite materials. By using this advanced and multifunctional machining center, customers can obtain the maximum flexibility, being able to perform any type of modelling and trimming operations on hulls, decks and components without distinction.

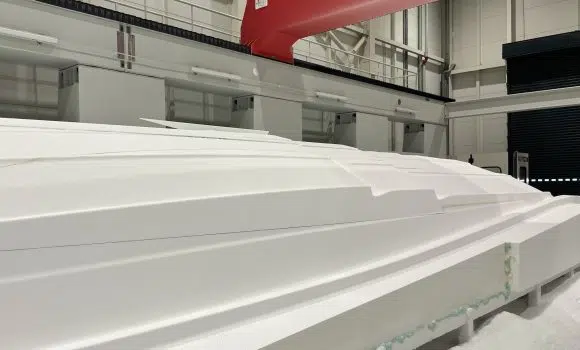

Belotti NAVY 20062 center at Lavrio production site is a high speed machining center with 5 simultaneous axes, featuring a motorized suspended bridge structure sliding on the two extremities, made of very thick welded heat treated steel which ensures long-term stability and greater machining accuracy.

The machining center has been equipped with a performance head with a 15 kW electrospindle at 12,000 rpm, granting high-speed milling on materials used in the marine industry such as polystyrene, polyurethane foams and epoxy paste.

Belotti NAVY 20062 machining center’s main technical features:

- Perimeter protection with front doors opening and pressurised dust protection bellows;

- SDS measure system;

- 3D measuring probe with radio transmission;

- Montronix: vibration monitoring system;

- 16-position automatic tool changer

- NC: Siemens.

Visit the following websites for further informations about Technohull® shipyard: