The long-standing collaboration between Dallara and Belotti, launched in 2016, has been rooted from the very beginning in a shared vision: the relentless pursuit of performance, with no compromises on safety, quality, or precision.

Founded in 1972 in Varano de’ Melegari (PR) by Engineer Giampaolo Dallara, Dallara Automobili is now a symbol of Italian engineering excellence and a benchmark in the pioneering use of composite materials across the automotive, supercar, and motorsport sectors. The company is the exclusive supplier of single-seaters for several championships—including IndyCar, Formula 2, and World Endurance Championship —and serves as a strategic partner to prestigious brands such as Alfa Romeo, Audi, Bugatti, Ferrari, Lamborghini, and Maserati.

THE CONTEXT

The pursuit of high performance and absolute precision—within a context where every single component makes a difference—requires continuous investment in increasingly advanced manufacturing technologies, capable of meeting the demanding standards of the racing and supercar sectors. In these industries, where the use of carbon fiber is essential to achieve lightness, strength, and speed, the challenge is twofold: to maximize machining quality and to ensure process reliability for every individual component.

THE SOLUTIONS

The Belotti FLA CNC center for Dallara Compositi

To address this challenge, Dallara selected Belotti as its technology partner for the machining and milling of composite materials. The collaboration began in 2016 with the installation of the first Belotti FLA 6526 5-axis CNC center, and has since grown stronger through the progressive adoption of increasingly advanced, next-generation solutions. This first investment, installed at the Dallara Compositi plant in Stradella di Collecchio (PR) and equipped with a parallel-motion Twin Shuttle loading/unloading system, proved essential for performing high-speed trimming operations on composite materials.

The Belotti MDL machining center for the production of the “Dallara Stradale”

In 2018, to support the production of the Dallara Stradale—the company’s first road car—Dallara acquired a second Belotti MDL 3048 5-axis machining center, highly valued for its operational versatility. This strategic investment was designed to support the ambitious goal of producing 600 units of the Dallara Stradale over five years, the race car for road use launched in 2017 by Engineer Giampaolo Dallara.

“When we started working on the Dallara Stradale, we needed a car that delivered the performance of a race car adapted for street use. That clearly required equipment with very specific characteristics in terms of precision, safety, and carbon fiber handling. The key feature that led us to choose the Belotti MDL 3048 machining center was undoubtedly its versatility—specifically, the ability to change tools quickly and easily, which resulted in a roughly 40% reduction in the machine cycle time required for our operators to carry out machining operations,” said Andrea Pontremoli, who currently (2025) holds the position of President of Dallara Automobili.

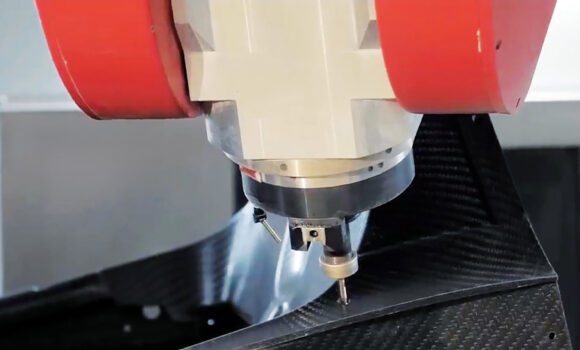

Thanks to its 5-axis cutting head with a cast iron fork structure and hydraulic brakes, floor-integrated dust extraction grids, and an 80-position tool changer composed of two horizontal double-chain magazines with pick-up tool retrieval, this Belotti MDL Series machining center ensures not only an enhanced and more efficient production process, but above all, extreme precision in machining complex carbon fiber components such as monocoques, which—through bonding—must integrate seamlessly with subsequent manufacturing stages.

A second Belotti MDL machining center for the “Dallara EXP”

The trust in Belotti machining centers was later reaffirmed in 2021 with the introduction of a third Belotti 5-axis CNC milling machine, model MDL 3048, installed at the Dallara headquarters in Varano de’ Melegari (PR). This investment was aimed at enhancing milling and trimming operations on structural composite components, including the carbon fiber monocoque used in the production of the “track day” variant of the Stradale, named Dallara EXP.

“Surface preparation is a delicate phase, but what’s truly critical is the machining process—because in just a few minutes the entire value of the component can be compromised,” said Davide Seletti, CEO of Dallara Compositi. “Having a system that is reliable, precise, and repeatable over time—one that delivers consistent performance from commissioning to maintenance, and that can promptly detect any anomalies—is absolutely essential for Dallara. At this critical stage, even after all processes have been correctly executed, there’s still a risk of losing the part. That’s why it’s vital to rely on the machine, the tool, and the operator—trained and prepared to run it at its best,” concluded Seletti.

This third Belotti machining center is equipped with a thermal shift control system (interfacing with the machine’s NC), a 200-position tool changer, and a touchless tool pre-setting system.

Two Belotti FLU 2617 5-axis machining centers for Italy and the USA

In 2023, the collaboration continued with the purchase of 2 new Belotti FLU 2617 CNC machining centers, installed at Stradella di Collecchio (Italy) and at the Dallara Experience Hub headquarters in Indianapolis (USA). Both systems were integrated into their respective production departments for the manufacturing of resin models and profiling of carbon fiber components. Each machining center is equipped with:

- Performance head with electrospindle up to 25 kW

- 30-position carrousel tool changer

- Advanced dust extraction system and tool air-blow

- MyB IoT Suite with Teleservice, Advanced Log, and bMaintenance

- Numerical control: Heidenhain

THE BENEFITS

The purchase and use of Belotti CNC machining centers have enabled Dallara to:

- Reduce cycle times by up to 40%, thanks to the versatility in tool management.

- Ensure repeatability and consistent quality on critical components such as monocoques.

- Optimize the entire production process through customized solutions.

- Expand production capacity in the United States as well, while maintaining the same quality standards.

Throughout this journey, the mutual exchange of experience and technical expertise between the Belotti and Dallara teams has been essential in designing and delivering highly customized technological solutions for the production of complex carbon fiber components, ensuring reliability and high performance at every stage of the process.

To explore the full range of Belotti CNC machining centers: https://www.belotti.com/en/cnc-machining-centers/

Please note that the statements by Andrea Pontremoli and Davide Seletti are featured respectively in the video documentaries “Lords of Carbon – La storia dei materiali compositi” and “Lords of Carbon – Dance of Danger,” curated by Davide Cironi and produced by Belotti SpA.