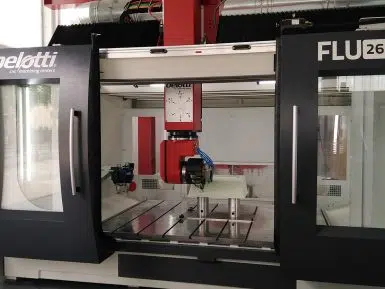

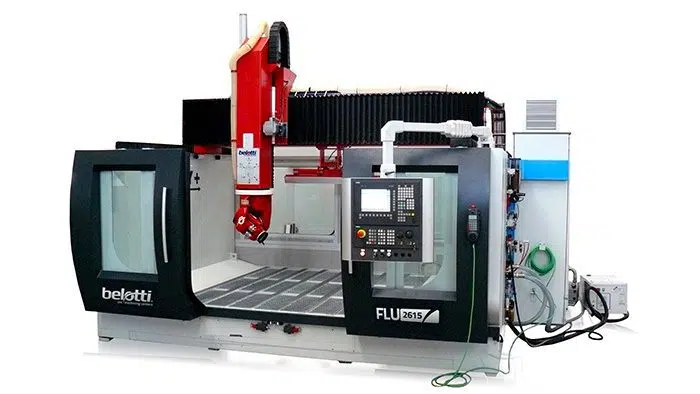

FLU Series

5-axis machining centers for milling resin patterns and aluminium moulds and for trimming composite materials.

Belotti FLU machining centres have a rigid structure specially designed to dampen vibrations and are more suitable for high-speed milling of resin models and aluminium moulds.

Description

Belotti FLU machining centers ensure high rigidity and stability thanks to the welded and heat-treated steel structure, available in the monolithic or double shoulder structure, indicated where a greater volume of work is required.

The special architecture of the milling machine allows total accessibility to the work area, offering the possibility to load both dimes and particularly heavy pieces using a forklift or a overhead crane.

The high-speed processing allows a reduction in cycle times while ensuring an excellent quality of the finishes.

Belotti offers a wide range of configurable and customisable tables based on specific production needs.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Automotive

- Patterns and moulds

- Medical

- Design and furniture

- Checking fixtures

- Packaging

- Aerospace

Materials

- Resins

- Composites

- Light alloys

- Technical plastic

- Plastic

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 2,6/4 m | 1,7/1,8/3,2 m | 1/1,3 m | +/- 270° | +/- 120° |

| Speed | 80 m/min | 60 m/min | 44 rpm | 40 rpm | |

| Spindle | From 15 kW up to 22 kW at 24.000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 8 to 60 positions, also with exchange arm | ||||

| Linear accuracy | ≤ 0,02 mm/m for linear axes | ||||

| Rotary accuracy | +/- 12 arc sec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 102/157″ | 67/71/126″ | 39/51″ | +/- 270° | +/- 120° |

| Rapids | 2,032 ipm | 1,524 ipm | 44 rpm | 40 rpm | |

| Spindle | From 20 HP up to 30 HP at 24,000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 8 to 60 positions, also with exchange arm | ||||

| Linear accuracy | ≤ 0,0012″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 12 arc sec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns (0,0002″) resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

Accessories

Linear scales

Direct incremental measuring system for all linear axes with graduated metal and pressurized line.

Two models are available:

- in a single body with glass optical band for lengths up to 4 m;

- in modular body with steel optical band for lengths from 4 m up to 72 m. This model is not affected by temperature variations compared to the steel band version.

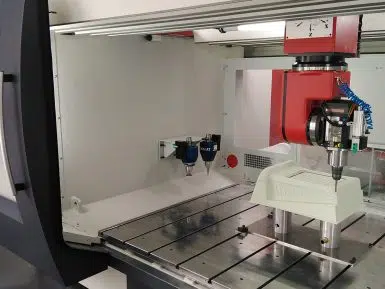

HP2 head (high performance)

Single-shoulder machining unit designed by Belotti S.p.A., accurate, reliable and with clean and compact shapes.

The special monobloc structure in cast iron ensures high standards of rigidity, temperature stability, minimizing vibrations during the manufacturing process. The High Performance 2 head is equipped with roll bearings reinforcing the head and the C axis in order to decrease the vibration and therefore increase the rigidity of the head itself.

Dust suction grids

The machining centre is equipped with two dust suction grids embedded into the back panel, at the working table height, that can be connected to the dust suction system by means of rear collectors.

Total enclosure with moving roof - FLU

The total enclosure, made of sound-absorbing panels, is designed to guarantee compliance to the current European noise rules for machining centers.

The automatic upper doors have a suitable opening for loading of parts through bridge crane.

Manual lower doors have a wide opening to enable loading of pieces according to the machine strokes.

Upper rolling shutter

Motorized rolling shutter that limits the escape of chips from the workstation area, making the opening and closing task easy and quick and allowing the overhead travelling crane loading.

The special translucent fabric guarantees ample light in the work area, already artificially illuminated.

Cooling liquid system with chip conveyor

Contact us for product information, technical support or spare parts requests.