8 June 2022

The industrial automation of production plants is shaping a new manufacturing ecosystem and a new way of working. Automating industrial processes means creating and implementing technologies capable of managing and controlling production phases in a fully automatic and unattended manner, thus defining an innovative approach to manufacturing.

Innovation—namely the pursuit and realization of pioneering, cutting‑edge solutions—has always been at the core of Belotti’s corporate vision.

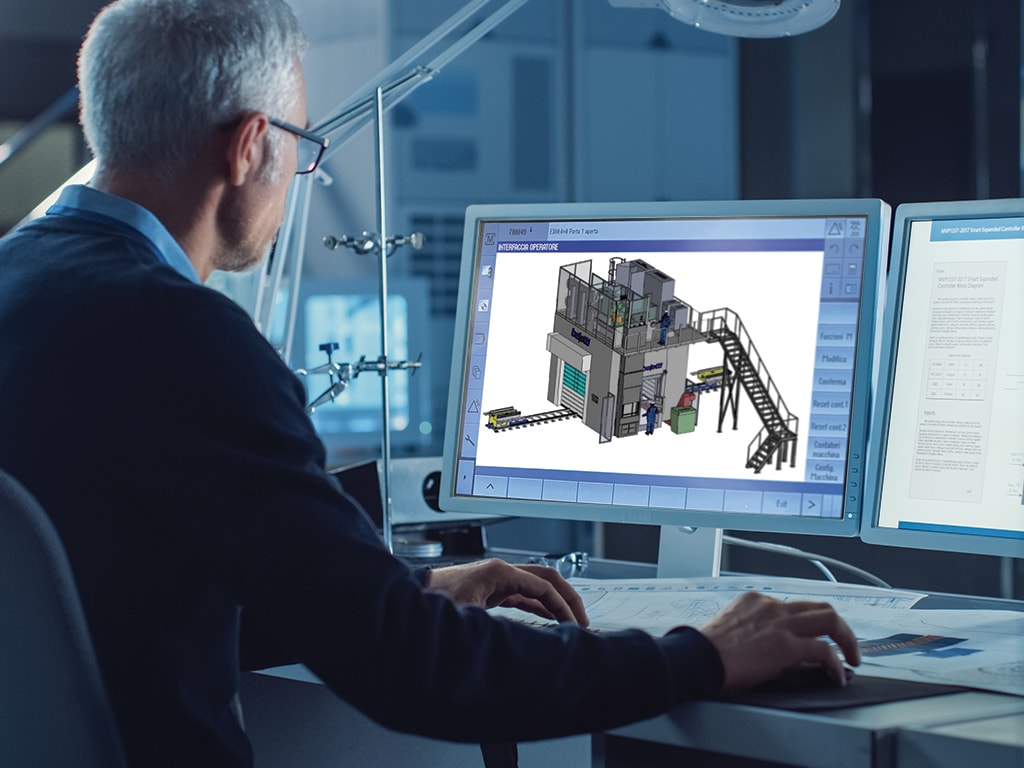

From this vision and from the needs of its customers, Belotti Automation was born: the division dedicated to the design and development of automated lines and robotic cells complete with hardware and software.

Companies are increasingly seeking solutions that can protect them from unexpected events and inefficiencies. To meet this need, Belotti has invested in developing a specialized division focused on designing, engineering, building, and supplying turnkey automated solutions capable of automating production processes and increasing productivity.

Cartesian manipulators, robotic cells, automatic warehouses, conveyors, and flexible feeders are designed and built by Belotti—confirming the company’s manufacturing DNA—integrating anthropomorphic industrial robots, AGVs, vision systems, and supervisory systems.

Belotti Robotic Automation

Inside factories, automation is increasingly used to boost production efficiency: today, three million industrial robots are installed and operating worldwide.

For over forty years, Belotti has supported major players in high‑tech sectors (automotive, aerospace, railway, and marine), providing CNC machining solutions for composite materials, plastics, and light alloys. Over time, the company has consolidated its role as a key technological partner and now also offers its expertise in developing customized robotic solutions to automate production processes.

Starting from the first modular cell, Belotti Integrale, created for the assembly line of Automobili Lamborghini’s Super SUV Urus, Belotti’s robotic systems now play an increasingly central role in customers’ new production paradigms, contributing automation both upstream and downstream of CNC machining. A flagship example of this activity is the robotic cell where a CNC machine and two anthropomorphic robots share the same control software.

A single technological partner across the entire line

A concrete advantage for customers who rely on Belotti to automate their production lines is having a single point of contact for every technical requirement. Belotti’s Service team—already known for its support on machining centers—ensures expertise and prompt intervention for any technical issue that may arise on the installed line.

More automation in manufacturing and the benefits of choosing Belotti’s robotic solutions

Where automation once seemed unsuitable, today—thanks also to the training and consulting provided by leading companies in the sector—long‑standing prejudices have been overcome. Manufacturing companies increasingly rely on automation to gain competitive advantages and improve the efficiency of their production cycles, especially when managing large volumes.

Moreover, government incentives introduced by many industrialized nations, including those promoted by the Italian Government, are encouraging companies to take advantage of tax benefits and funding opportunities to acquire technological equipment that supports process automation.

The Belotti Robotic Automation division can support these companies by significantly increasing productivity and efficiency, reducing costs and time, and offering numerous benefits:

- Cost reduction: relying on robotic automation to complete a production cycle protects the company from unexpected events and physiological drops in efficiency, freeing it from issues related to specialized labor availability.

- Increased productivity: minimizing the risk of mistakes reduces waste and boosts productivity within a Lean Manufacturing perspective. The ability to accurately predict workflow also enables better monitoring and management of production. Personnel, freed from repetitive tasks, can focus on higher‑value activities, increasing their contribution to the company’s success.

- Greater safety: handling heavy objects or materials can be entrusted to robots and automated processes, making the production line safer for employees.

- Space optimization: integrating automated cells or lines within production allows for a more logical and functional use of space.

- Return on investment: thanks to its experience as a system integrator, Belotti supports customers in choosing the most suitable automation for their specific needs, creating faster, safer, and more precise workflows. As a result, a Belotti Automation robotic integration can achieve ROI in some cases in less than one year.

Precision and reliability: uncompromising quality

Belotti designs, develops, and manufactures CNC machining centers for milling, drilling, and trimming advanced materials, composites, plastics, and light alloys. These technologies have always been valued by customers for their ability to bring a high level of innovation to production environments. This deep expertise in delivering increasingly high‑performance CNC solutions now also permeates the division dedicated to robotic automation.

Handling, manipulating, and positioning the workpiece are fundamental phases for the successful completion of the process.

Belotti is fully aware of this, which is why automatic warehouses, conveyors, shuttles, AGVs, Cartesian manipulators, and anthropomorphic robots are conceived and built to ensure maximum reliability. The lines designed and installed by Belotti result from an engineering process that considers three key elements:

- Productivity: handling cells equipped with top‑tier robots featuring dedicated grippers and mechanical systems ensure speed and efficiency.

- Flexibility: tool magazines built ad hoc for each customer and intermediate stations before loading (in some cases equipped with 2D and 3D artificial vision systems) are designed to allow extremely fast retooling during batch changes and high production autonomy.

- Quality: using the robot as a positioning system for optical sensors, handling lines can be equipped with inspection systems capable of objectively assessing product quality through surface, dimensional, or assembly checks.

This engineering synergy enables constant monitoring, precision, and reliability—qualities for which Belotti machining centers are appreciated both domestically and internationally.

Belotti’s industrial automation systems are not limited to CNC machine tending but also include complete turnkey projects for a wide range of production activities across different industrial sectors. Numerous projects are currently underway within the Belotti Robotic Automation division, some of which—due to their high complexity—are set to become milestones in the company’s growth, both technologically and in terms of human capital.