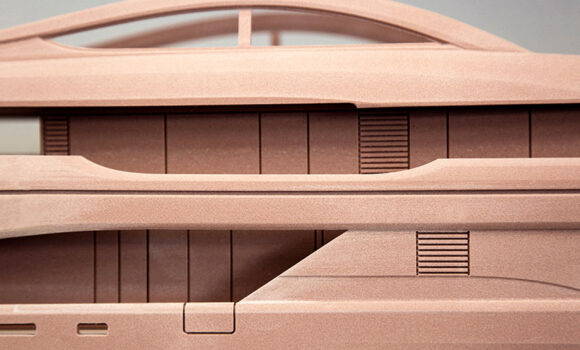

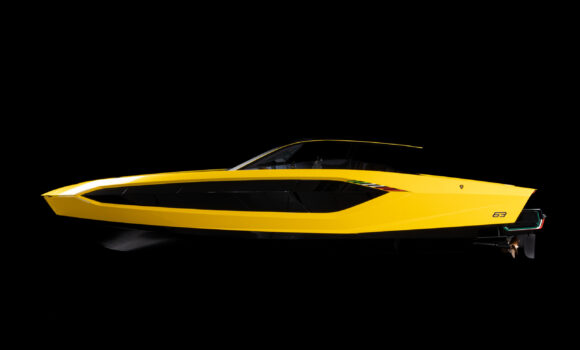

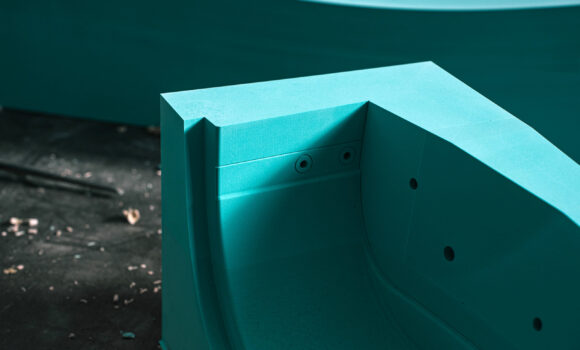

For over twenty years, Model Maker Group, a company based in Itri in the province of Latina, has been manufacturing nautical prototypes, reproducing every detail of boats, in particular yachts and superyachts, with finesse and mastery. A real boutique where unique models and prototypes are born, created by focusing on the ideas and requests of customers, promptly transformed into projects where the attention to details and finishes aims at perfection.

The Model Maker Group’s nautical models are therefore born from great craftsmanship, supported by the most modern technologies for prototyping, real jewels designed to stand the test of time. Creations intended both for future owners of boats, providing them with a perfect scale reproduction with which to imagine future routes to be sailed, and for shipyards as a marketing tool capable of offering a global and concrete vision of boats on the occasion of the most prestigious boat shows.

THE CONTEXT

Spread over two locations for 1,900 square meters, Model Maker Group carries out over 350 processes/year including projects, replicas and refits thanks to an internal team of expert model makers in an environment that has always been open to innovation and to the adoption of extremely precise production technologies.

In 2018, the company faced an increase in demand within its reference market and therefore considered the purchase of a new machining center with the triple objective of:

- optimizing the milling process, which was already carried out with 3-axis centers,

- improving the quality level as well as machine times,

- entering new markets.

It is within this scenario that the purchase of a new Belotti FLA 5518 cnc machining center, the best-selling Belotti Series for high-speed 5-axis machining of composite materials, plastics and resins, fits in.

THE SOLUTION

After the purchase of the first center in 2018, having overloaded the production capacity of the machine, the company has therefore decided to expand its machine range by purchasing a second Belotti machining center in 2023, identical in structural characteristics and accessories to the first model.

“After carefully evaluating the offer on the market of different competitors,” says Giuseppe Capobianco, MMG Chief Operation Officer, “we chose Belotti because, in addition to offering a valid product, it paid particular attention to our needs. The company has proven to be a true partner not only for the supply of reliable and precise machining centers, but also for the assistance provided both in the installation phase but above all in operational continuity, year after year, supporting us even in the summer periods when our machining centers have the greatest production load“.

MAIN TECHNICAL FEATURES AND ADVANTAGES

The Belotti machining center FLA 5518 purchased in 2023 has a fixed table structure, the most rigid and precise solution ever, housed in an integral enclosure to ensure compliance with noise regulations and a clean and safe working environment.

The 5-axis machining on the structural parts of the high-density polyurethane resin models is carried out using an HP performance head with a 15 kW and 18 kW electrospindle (max. rotation 24,000 rpm), in combination with a rotating axis pneumatic locking system.

“By choosing Belotti, we were able to re-engineer our production process, thus providing our customers with very high quality standards. We have been able to create models of considerable size that were completely beyond our imagination (over 3 and a half meters) and we have opened up to new sectors such as the production of carbon moulds, but also the creation of aesthetic components on a 1:1 scale for yachts,” Capobianco concludes.

The two Belotti FLA 5518 machining centers at Model Maker Group are also equipped with:

- 18-position carrousel tool changer

- DRF option

- Air blowing on the tool

- SDS Measurement Cycle

- Belotti MyB IoT Suite, with BES and bCare modules

- Numerical control: Siemens One

BELOTTI SERVICE

Central to the maintenance of the performance of Belotti machining centers over time is the planning and execution of maintenance activities. Since the beginning of the collaboration, Model Maker Group has shown itself to be sensitive to this issue, thus signing a preventive maintenance contract on FLA machining centers. The goal is to ensure performance over time in terms of accuracy and machining reliability, controlling critical components and thus reducing the risk of production inefficiency.

Thanks to the Belotti Compact package, the machining centers at Model Maker Group are periodically checked by specialized Belotti technicians and subjected to maintenance, verifying their geometry and providing a report at the end of the intervention with the results obtained.

Intervention planning also minimizes the likelihood of unforeseen downtimes.

For more information on Belotti machining centers and after-sales services, please contact us via the contact section.