30 May 2025

Within the Belotti Innovation Hub, located at the Modena facility, there is a dedicated Service area for the technical maintenance and assistance of machining centers, as well as for electrospindles repair. This area, equipped with specialized tools and managed by expert technicians, serves as a reference center for field service technicians operating in central and southern Italy.

Among all post-sales activities, the electrospindle repair service plays a fundamental role for Belotti customers as it minimizes machine downtime while maintaining productivity, thanks to a comprehensive stock of high-turnover spare parts.

Steps in the electrospindle repair process

The electrospindle repair process starts with the shipment of the component to the Belotti Service center in Modena, where our specialized technicians—renowned for their precision and reliability—take charge and manage the entire repair cycle, which is divided into key phases:

- Analysis and Diagnosis

During this initial phase, the spindle is cleaned, completely disassembled, and thoroughly analyzed to detect any potential issues and define the most effective repair procedure.

Our technicians provide a detailed photographic report, offering customers a clear overview of the spindle’s condition and the necessary interventions for optimal restoration. These interventions are subsequently outlined in a formal repair proposal.

- Repair, Reassembly, and Testing

Once the procedure and the corresponding proposal are approved, Belotti technicians proceed with the spindle’s repair. The process concludes with the reassembly of all components, followed by the final testing phase, which includes three specific tests:

-

- Stator Testing / Signal Testing: Electrical components of the spindle (stator, windings, and sensors) are thoroughly tested using oscilloscopes and advanced diagnostic tools to confirm proper operation or identify any parts needing replacement.

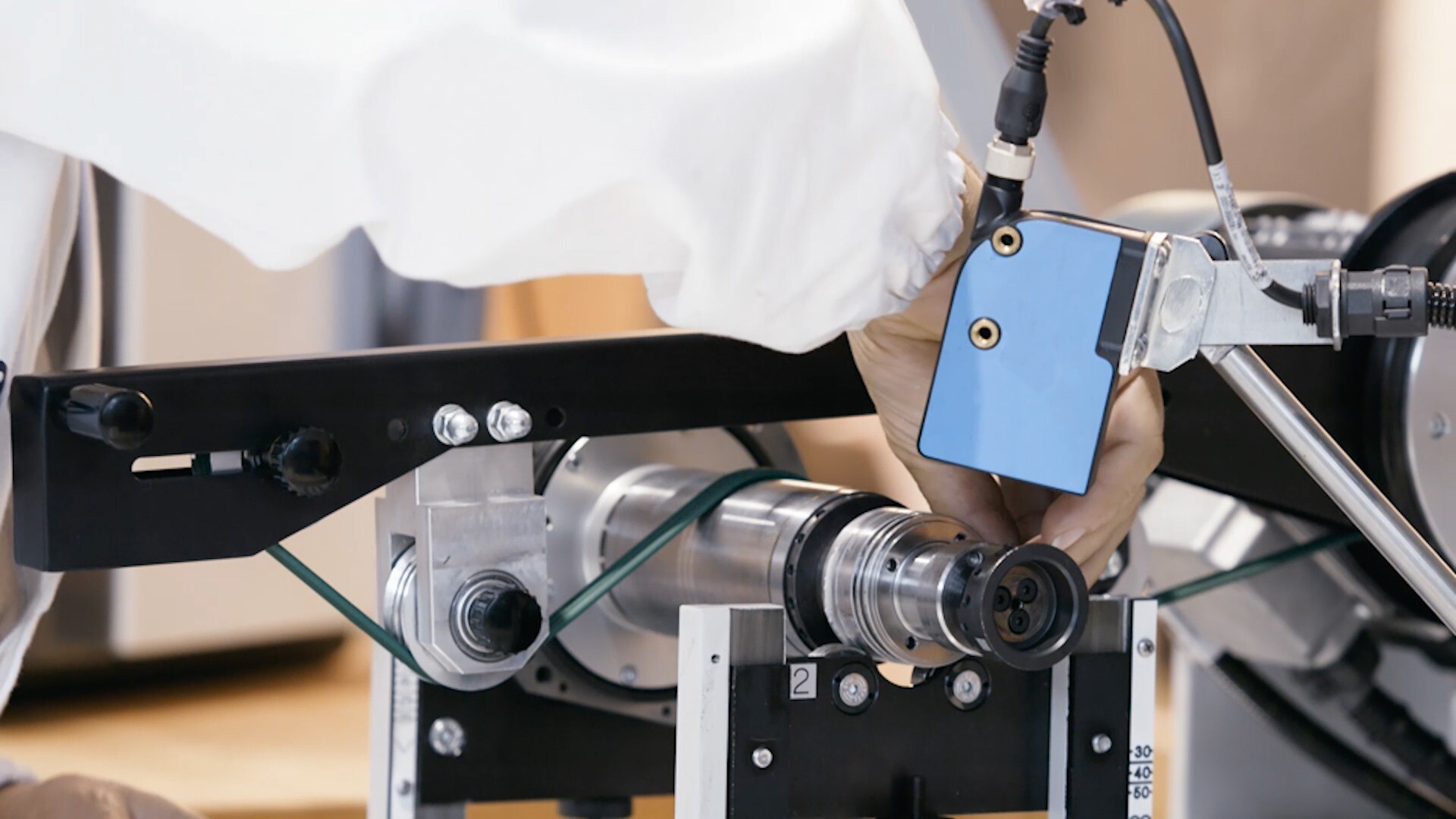

- Balancing: Using dedicated equipment, balancing is carried out to minimize spindle shaft runout, preventing imbalance or excessive vibrations at high speeds. All spindles repaired or overhauled at our specialized department undergo this process after reassembly in order to issue a report detailing runout measurements recorded during testing.

- Running-in: The final phase involves a comprehensive functionality test. The spindles are run through specific cycles to ensure proper bearing break-in, followed by testing at maximum speed to guarantee perfect operating conditions even during deployment on the machining center. Thanks to the special test bench, various parameters are measured and summarized in the final test report provided to the customer upon delivery.

We have collected the most frequently asked questions about the electrospindle repair process here: FAQ

For more in-depth information on Belotti after-sales services, please visit the Belotti Service section, or contact us by filling out the form on the Contact page.