5 June 2023

In recent years, companies specialized in industrial automation have being providing effective solutions to the growing demand from the manufacturing industry to produce in an even more flexible, optimized, and sustainable way.

In fact, manufacturing companies have shown an increasing propensity for tailor-made solutions, that can perfectly adhere to their specific requirements and business development strategies. This trend has led many industrial automation companies to offer technologies and design highly versatile production processes, easily and quickly adaptable to the customer demands, providing bespoke solutions in a timely manner.

THE CONTEXT AND THE SMART FACTORY MODEL

Modern industry must know how to continuously adapt to the rapidly evolving economic contexts, in order to survive in an increasingly competitive and dynamic market. The Smart Factory represents one of the most significant expressions of Industry 4.0 (also called the “fourth industrial revolution”), a digital transformation movement that has introduced new models for conceiving the production systems of the present and the future.

Thanks to the digitization of production processes and services – through the adoption of new technologies such as artificial intelligence and machine learning – and the use of advanced solutions such as automation and robotics, companies can benefit from faster processing, greater precision and product quality, waste reduction and lower production costs. In short, the digitization of production processes ia a key, competitive advantage for manufacturing companies, which must be able to satisfy their customers’ needs quickly to stay competitive in the global, and fast-paced market.

Companies active in the industrial automation sector are revolutionizing the manufacturing landscape, making a significant contribution in terms of innovation in the industrial production processes through Robotic Process Automation (RPA) and hyper-automation solutions.

Innovation has always been one of Belotti’s vision cornerstones, leading the company in the development of state-of-the-art technologies for many application industries.

BELOTTI ROBOTIC AUTOMATION

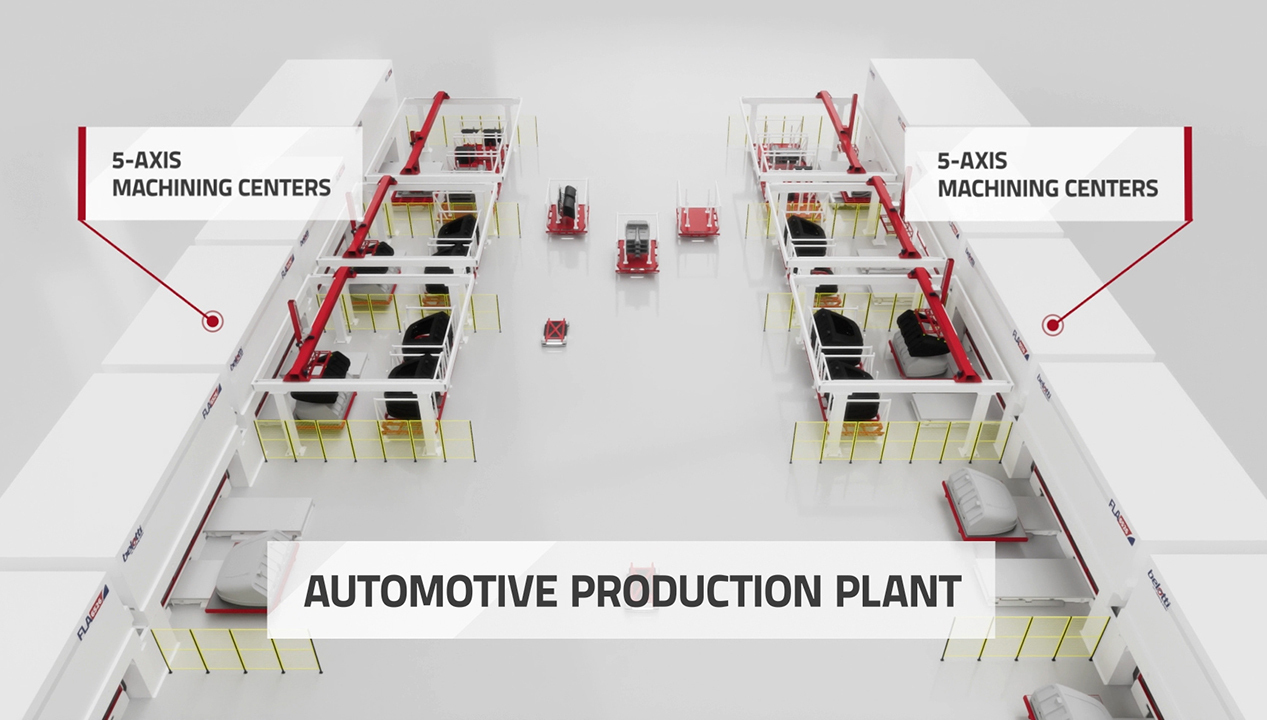

The Belotti Robotic Automation business unit was established to address the needs of industrial automation solutions of companies involved in the raw materials’ machining or components’ production, designing and manufacturing automated lines and turnkey robotic cells equipped with cutting-edge hardware and softwares, enhancing the overall performances.

Belotti designs and provides automated solutions for different application needs, including equipment such as:

- Cartesian manipulators;

- Robotic cells;

- Automated warehouses;

- Flexible conveyors and feeders;

- Anthropomorphic industrial robots;

- AGVs (Automated Guided Vehicles);

- Vision systems and supervisory controls;

Thanks to its multi-year experience in the industrial machinery sector and a team of professionals specialized in industrial automation systems and mechatronics, Belotti can lead companies through every stage of the automation process, from design and implementation, up to training and consulting.

Automating production processes means creating and deploying technologies able to manage and control the production phases in a completely automatic way, minimizing the need for human intervention, improving the approach to production, and promoting predictive maintenance applications.

For over than forty years, Belotti has collaborated with world-renowned players in high-tech sectors, providing them with solutions for 3-and 5 axis NC machining of composite materials, plastics, and light alloys. These are the main sectors where Belotti technologies are installed and used:

- Automotive

- Aerospace

- Marine

- Railway

- Patterns and moulds

- Checking fixtures

- Thermoforming

- Design and furniture

- Energy and building

- Packaging

- Medical

Belotti proposes itself as a single, technological partner for its customers, providing cnc machining centers and robotic automation solutions to leverage the full potential of the investments and guarantee production continuity.

The most sought-after systems include solutions to automate the upstream and downstream phases of numerical control machining, up to robotic cells where loading/unloading and handling of the components are managed by anthropomorphic robots.

Belotti also offers solutions to automate logistic processes alongside the entire production cycle: automated warehouses to optimize material storage and reduce retrieval times, AGV systems for automatic component transportation within the factory, and vision systems for traceability and quality control of the products.

Belotti’s automated solutions are scalable and customizable according with customer requests, ranging from small robotic cells for specific part processing to fully automated production lines.

Belotti’s Robotic Automation business unit is well-structured and has the resources to serve the customers as a single partner on all technical issues related to the production line: from CNC machining centers to robotics, up to automated logistics and vision systems. This allows companies to have comprehensive support and greater efficiency in managing production processes, training, and technical assistances.

Download the “Belotti Robotic Automation” brochure or contact the business unit.