22 January 2021

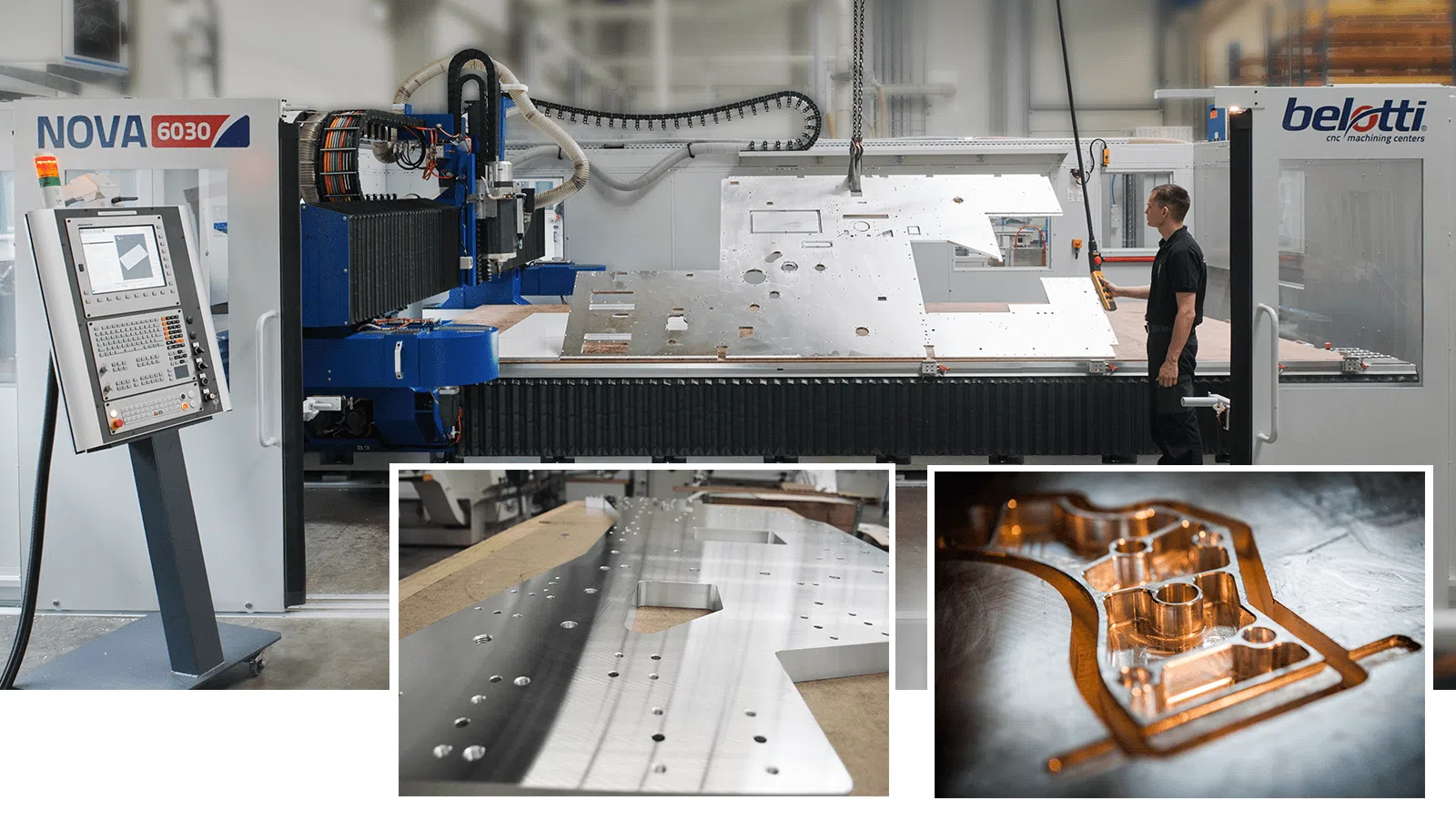

BELOTTI EXTENDS ITS RANGE OF CNC CENTRES FOR PLASTICS AND COMPOSITES PANEL PROCESSING AND FOR ALUMINIUM PLATE MILLING.

The different machining operations on large aluminium, plastics and composites sheets, all share the absolute must of high productivity coming from the current market trends. Therefore, at the core of any industrial production, it lays the ability to promptly respond to the varied demands of the market, always meeting the expected quality standards.

To help customers pursue this goal, Belotti has developed Nova and now launches Nesting, two automated and extremely flexible technological solutions. These Belotti CNC centers always operate in accordance with pretty high-quality standards and tight tolerance ranges, machining even small and very detailed finished parts out of blank aluminium sheets or other materials’ large plates up to 80 mm thick.

Thanks to several technical advantages, both Nova and Nesting machining centres represent a reliable solution for different applications such as mechanical engineering, checking fixture, packaging, aerospace and automotive. Their ability to carry out unattended operations for the entire cycle time allows to reduce the operator cost significantly, increasing the overall efficiency.

Nesting, the last born series of Belotti 3-axis machining centres – with its monolithic structure, streamlined configuration possibilities and reduced consumption – flanks the premium series Nova. This latter solution is already well-established on the reference markets thanks to its undisputed performances: extremely high precision, high chip removal rate, machining versatility, reliability and ease of use.

The main technical features and the key performance indicators of Belotti technology apply to both Nova and Nesting series and are actually tuned and customised to the customers’ specific needs.

The two machine lines could be the right fit for different manufacturing markets – mechanical components and structures for automatic and packaging machines, checking fixtures, aerospace and automotive components in aluminium and technical plastics – as they guarantee an excellent return of investment.

Belotti Nesting, the smart and compact 3-axis CNC centre, shares the Nova’s large worktable (up to 4 x 2 m) and is best suited to machining pieces up to 30 mm thickness, always guaranteeing the accuracy and the efficiency (material, time and cost optimisation) of all Belotti solutions.

Nova 5-axis machining centre, available in many different configurations through its numerous accessories, represents the core of the company’s technological know-how and how this can turn into a real competitive advantage for customers, thanks to the close collaboration with the sales team.

The benefits and the most relevant technical features of these Belotti solutions are:

MAXIMUM ACCURACY AND FINISHING QUALITY:

- the enhanced rigidity of the bridge, due to the monolithic structure equipped with double guides on both sides of the basement

- the possibility of machining even large workpieces while preserving the great finishing quality, thanks to the double motor on both sides

- the total backlash recovery, thanks to the linear glass scales that operate in synergy with the Dual Drive System on both X and Y axes

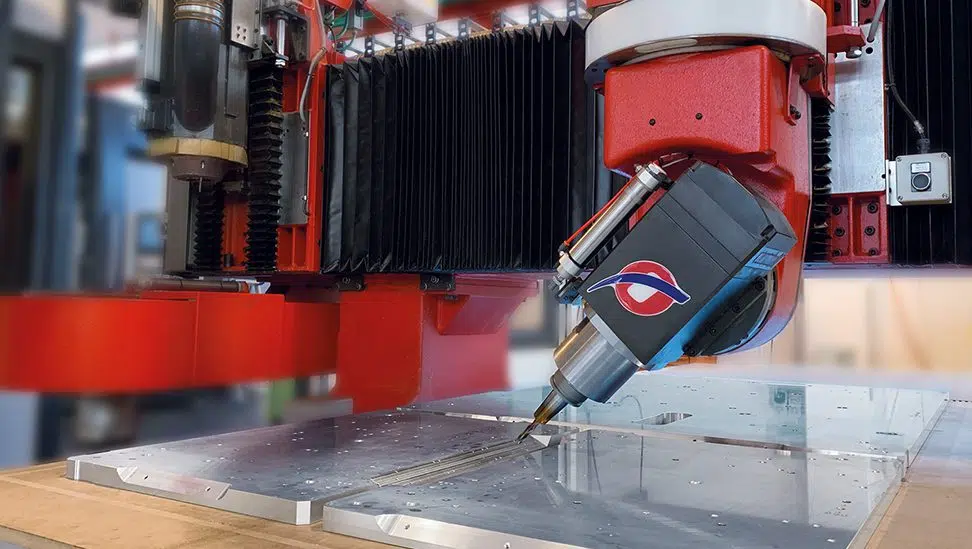

- the extremely smooth movements coming from the machine’s layout and the cutting heads’ motors – orchestrated with the other technological features – assure great surface quality with a mirror finishing effect.

INCREASED PRODUCTIVITY:

- the great capacity of chip removal of the electro-spindles up to 30 kW, combined with the cleanliness of the working area during the cutting operations, thanks to the NC-controlled and motorised suction hood

- a significant time-saving advantage during the workpiece clamping phase, thanks to dedicated clamping systems, even for small workpieces, and the worktable equipped with a transpiration or vacuum system. No set-up is required if compared to conventional systems (fixing and bracketing, clamping with screws or vices)

- the increased cutting federate together with a better milling quality, thanks to the lubrication system MQL combined with a rotary joint. The tool tip is always well lubricated during the milling process, thanks to the internal cooling liquid or air that avoids the tool overheating, the material melting and the chip sticking to the cutting edge

- the possibility of saving time in setting-up the milling programs, even in the case of complex geometries and operations, thanks to the CAD/CAM Easy Programming software plug-in.

GREAT VERSATILITY:

- the wide possibilities in terms of machining operations combined with the flexibility offered by the tool change. Its stocking capacity, customisable according to each specific needs, allows to significantly reduce the set-up phase between one machining operation and another

- the simplicity and speed of the workpiece positioning thanks to the probing system, which also allows to check the piece’s dimensions directly on the machine.

The new Nesting series together with the Nova series represent a further step towards the main company’s goal: providing full solutions able to meet the highest standards of accuracy and efficiency while satisfying the many and varied needs emerging from different markets – specifically, the high-speed nesting of plastic panels as well as the production of multi-layered checking fixtures and other mechanical components from aluminium sheets.