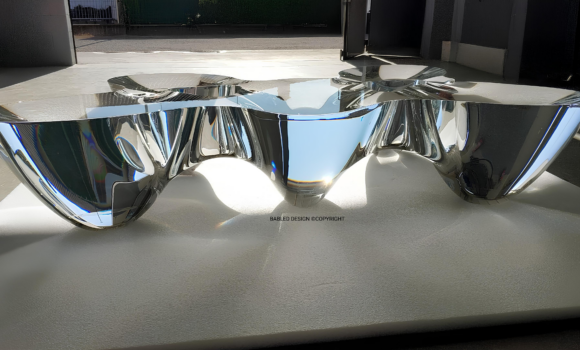

Transforming material into visual emotion is the art to which Esvoplex dedicates itself every day.

With over thirty years of experience in the field, enriched by specialized training in Germany at the historic company that invented PLEXIGLAS® (polymethyl methacrylate PMMA), Esvoplex is now a benchmark in the machining of layered and block plexiglas for the creation of custom elements in the furniture, architecture, luxury yachting, and fashion design sectors.

Over the years, the company based in Appiano Gentile (CO) has built its growth on the ability to combine expertise with creative vision, using cutting-edge machining technologies.

THE CONTEXT

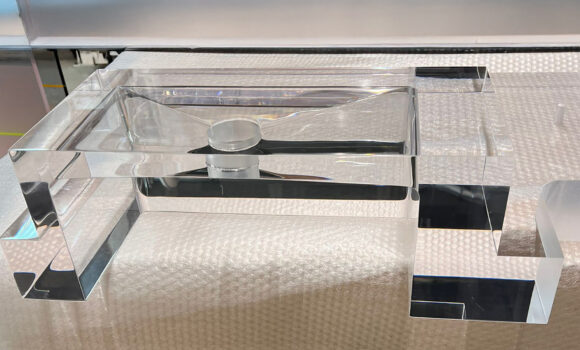

By using large sheets, rods, and blocks of pure plexiglas (up to 1200×2000×300 mm) processed in monolithic form—an innovative technique designed to offer clients endless possibilities for expression and application—Esvoplex creates unique furnishing accessories, iconic objects that blend functionality and beauty, technique and style.

With imagination as the only limit to its creative capabilities, Esvoplex finds it essential to rely on flexible and reliable production technologies for the direct machining of plexiglas.

THE SOLUTION

The collaboration between Esvoplex and Belotti was born from a shared vision: to create highly customized solutions and products that fully meet the demands of their respective clients.

This common tailor-made approach led to the decision to rely on Belotti and to add a Belotti FLA 4018 machining center to the equipment fleet—a 5-axis CNC milling machine designed to ensure maximum finish quality, stability, and precision, even in the most complex operations on thermoplastic materials.

The Belotti FLA Series 5-axis CNC center is the ideal technological solution for milling and trimming plastic and composite materials. The configuration chosen by Esvoplex perfectly meets the requirements for plexiglas machining, ensuring precision, superior finish quality, and repeatability of results. For Esvoplex, whose trademark is custom machining, this technology ensures the right mix of productivity and adaptability to bespoke workflows.

“Thanks to its practical and intuitive use and an extremely efficient and responsive Service, this Belotti FLA 5-axis machining center enables us to meet even the most demanding requests from our clients, ensuring precision, versatility, and speed of execution—even with the most complex geometries,” says Alfio Maci, partner at Esvoplex (founded by Emilio Sampietro – founder and president).

Installed at the company in 2024, the Belotti FLA 4018 CNC center (X-axis 4m, Y-axis 1.8m, Z-axis 1m) features a fixed table structure with aluminum vacuum tables equipped with channels for vacuum distribution and two vacuum zones. To ensure operator safety during machining, the machine is equipped with a perimeter enclosure with automatic doors and safety limit switches synchronized with the “cycle start.”

Plexiglas milling operations are carried out using a high-performance head supported by a pneumatic locking system for the rotating axes and direct encoders. The operating unit is also equipped with an automatic tool changer and a liquid cooling system that minimizes the risk of material overheating during complex operations, ensuring maximum precision and finish quality.

The entire system is monitored by the Belotti MyB IoT Suite, with the BES – Belotti Equipment Supervisor module, which allows the company to collect real-time processing data and optimize the production cycle according to smart manufacturing principles.

The configuration of the Belotti FLA 4018 machining center is completed with the following components:

- 8-position tool changer

- SDS measurement cycle

- Vacuum system

- Numerical control: Siemens One

THE BENEFITS

“Among the main technical advantages that led us to invest in the new FLA 4018 machining center are the complete absence of vibrations—which enables us to perform complex 5-axis machining operations with virtually perfect finishing—and the usable working height of 1 meter, which enables us to work effortlessly on plexiglas blocks up to 400 mm thick,” says Alfio Maci.

In a sector where form is substance, the quality of machining becomes an integral part of the design itself. And with the support of Belotti technologies, Esvoplex can continue to give shape to the endless creative projects of its clients.

For more information on Belotti FLA machining centers, please refer to the dedicated “FLA Series” page.