“Producing the best tailored suit for any type of product“. This is the mission of Tecno Pack, a company based in Schio (VI) specialized in the production of packaging machines and lines for more than 30 years.

Its products’ range includes solutions for all packaging applications to satisfy the many and often stringent requirements imposed by both the food and no-food sectors. From vertical and horizontal packaging machines to tray erectors, all models are produced at the headquarter. The high level of customization of each solution has led the company to invest in special equipment for the production of light alloy and plastic components that require extremely precise, reliable and at the same time flexible machining processes.

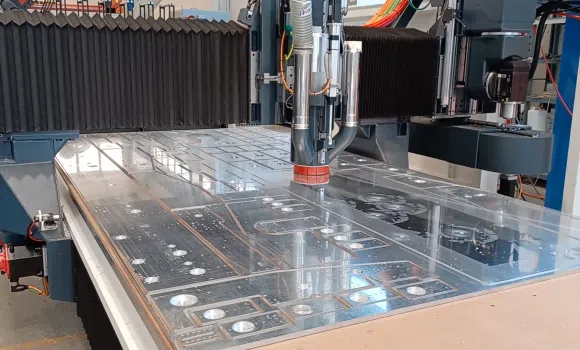

These demands have been met by the Belotti NOVA 6020S 3 and 5-axis numerical control machining center, currently operating at Schio plant, which enables the company to produce the multiple components needed for its packaging machines with the highest dimensional and surface finish accuracy.

The performances guaranteed by this technology has recently led Tecno Pack to purchase a second Belotti NOVA model 4020S machining center, expected to be installed in 2023.

The Belotti Nova Series confirms itself as the ideal solution to meet the most stringent requirements of the packaging sector and other industries. This specific 5-axis solution is equipped with a dual motor system on both sides (Dual Drive System) and Heidenhain axis locking brakes and encoders, which enable the machining of parts with complex shapes while ensuring quality and precision.

Ease and speed of tooling are ensured by the laser workpiece centering systems, which make the NOVA Series extremely high-performant: the result is a machining center that enables companies to increase productivity and competitiveness.

These are the additional technical features installed on Belotti NOVA6020S machining center operating at Tecno Pack company:

- 3-axis operating unit with electronic suction hood;

- 5-axis operating unit;

- Perimeter cabin with telescopic doors;

- 24-position chain tool changer;

- 15-position linear tool changer;

- Aluminium suction table with removable MDF panel;

- Chip suction system;

- Suction cup equipment for slab handling;

- Manual slab-holder warehouse;

- Belotti MyB IoT Suite;

- SDS measuring system;

- 3D probing system with radio transmission;

- Numerical Control: Fanuc.

For further information on Belotti machining centers, please contact us via our website Contact page.