Headquartered in Coventry, at the heart of the UK automotive industry, Envisage Group has earned a global reputation for engineering, design, and prototype manufacturing. Its portfolio spans luxury automotive brands, aerospace, and niche mobility projects, where creativity and technical expertise combine to deliver high-quality, bespoke solutions.

Growth has been fuelled by supporting OEMs and tier-one suppliers across the product development cycle, from concept to full-scale prototypes. To sustain this, Envisage continues to invest in advanced technologies that meet rising demands for precision, speed, and efficiency.

The company also holds AS9100:D certification, underlining its commitment to quality and continuous improvement.

THE CONTEXT

Meeting rising demand with greater in-house capacity

As customer demand increased, particularly from luxury automotive and aerospace clients, Envisage recognised the need to boost its machining capability. Reducing lead times, minimising reliance on external suppliers, and achieving exacting standards on materials such as aluminium, resin, and composites became strategic priorities.

THE SOLUTION

Two Belotti SKY CNC machining centres

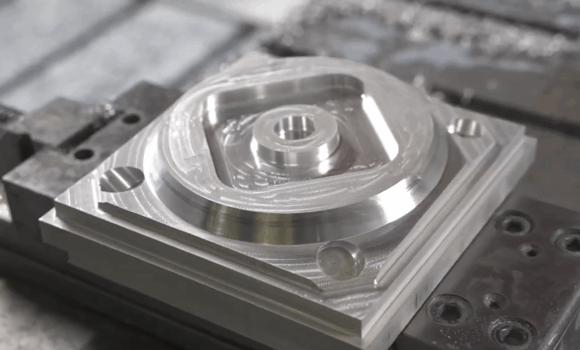

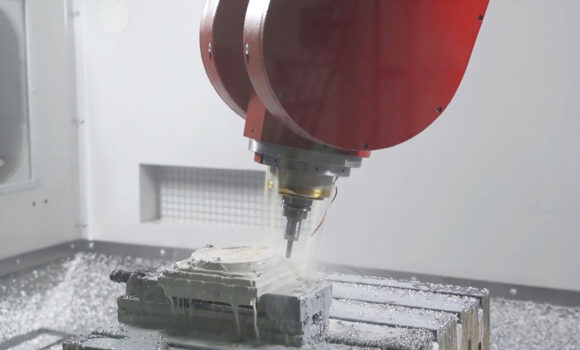

To expand capacity, Envisage invested in two new Belotti 5-axis machines – a Belotti SKY 2617 and a Belotti SKY 3630 – now operational at its Herald Way machining centre in Coventry. These machines enhance productivity, reduce costs, and ensure precision across a wide range of projects, from aerospace aluminium parts to full-scale vehicle mock-ups.

The Belotti SKY Series is engineered for high-speed, high-precision machining of composites, resins, and aluminium. With compact, monolithic steel structures, large working envelopes, and advanced safety systems, the Belotti SKY 2617 and Belotti SKY 3630 CNC centres allow Envisage to handle both small intricate parts and larger, complex components with ease.

Key features include:

- 5-axis milling heads for flexibility and accuracy;

- Robust steel structures and tables for stability;

- Automatic tool changers with up to 24 positions;

- Cooling, dust extraction, and vision systems for safety and efficiency.

THE BENEFITS

Tangible benefits: autonomy, precision, and flexibility

The installation of the Belotti SKY 5-axis machines has enabled Envisage to:

- Expand in-house capabilities and reduce outsourcing;

- Increase throughput while maintaining quality;

- Deliver both prototypes and small-series production with greater flexibility;

- Strengthen competitiveness in demanding markets.

By partnering with Belotti, Envisage reinforces its mission to merge creativity with manufacturing excellence, ensuring clients receive innovative solutions with uncompromising quality.

Discover more on Belotti SKY CNC centers.