For twenty-five years, FA.ST.MODEL, an Italian company based in the province of Monza and Brianza, has been producing polystyrene patterns and moulds of any size and complexity, offering its clients high product quality and fast execution.

By combining artisanal craftsmanship, automation, and technological precision—achieved through CAD/CAM programming—the company has specialized in the manufacturing of polystyrene foundry patterns, with or without core boxes, for a wide range of industrial sectors such as mechanics, energy, marine, and automotive, as well as the creation of highly evocative scenic installations for designers, exhibition setups, and theatrical and cinematic productions.

THE CONTEXT

In the polystyrene processing sector, especially in the production of large-scale foundry models, the combination of power and machining speed is essential to optimise productivity and costs. This is accompanied by the need for a spacious and well-organized work environment capable of handling large volumes of material to be milled while ensuring precision—a fundamental requirement for foundries and an absolute imperative in prototyping, where even the slightest deviation can compromise the functionality of the final product and slow down the entire development process.

THE SOLUTIONS

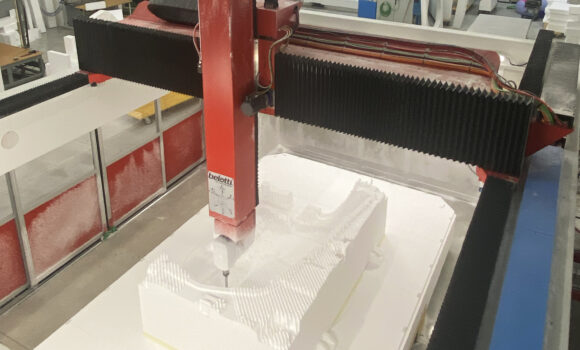

After an initial investment in a used CNC milling machine, the Belotti RO5 model, FA.ST.MODEL turned to a new 5-axis machining center, identifying the Belotti FLA Series as the most suitable technology for its machining operations. This series immediately proved to be a key ally for the company.

“The first purchase of a Belotti R05 machining center delivered great satisfaction from the very first use, even though it was a used CNC center. The real turning point came with the acquisition of the Belotti FLA 6532 CNC milling machine: its introduction into our machine fleet was a winning choice that yielded excellent results, significantly increasing our turnover and giving momentum to our company,” says Fabio Nava, CEO of FA.ST.MODEL.

Nearly ten years after this first investment, made in 2015, FA.ST.MODEL chose to renew its trust in Belotti’s 5-axis technology by purchasing a second Belotti FLA 5032 CNC machining center.

“The intuitive and rational use of the first FLA machining center led us, in 2024, to purchase a new Belotti FLA 5032 milling machine, slightly smaller but equally powerful and capable of interfacing with the most modern control systems,” Nava continues. “The two machining centers are perfectly interchangeable, which now allows us to work in parallel on both machines, achieving unmatched production capacity.”

Belotti FLA CNC machining centers represent the best solution for:

- High-volume trimming of composite material components.

- Milling of resin models.

The Belotti FLA 5032 CNC center installed at the Ornago production plant features a fixed table structure integrated into a perimeter enclosure with manual doors for quick and easy handling of large blocks. Protective bellows and the suction system help reduce dust emissions and noise levels while ensuring high production standards.

Polystyrene model milling operations are carried out using a Performance Head with 15 kW and 18 kW electrospindle, supported by a pneumatic locking system for the rotary axes.

The operating unit is also equipped with a liquid recirculation cooling system and a 16-position automatic tool changer.

THE BENFITS

The configuration of the Belotti FLA 5032 CNC center is completed by the MyB Software, the Belotti IoT platform for integrated and optimised management of machining centers within the factory environment. This software allows real-time monitoring, analysis, and optimisation of all activities, improving operational efficiency and process traceability.

“With the new Belotti MyB platform integrated into the CNC center, we can monitor all work phases. Now we can directly trace the model on the worktable, continuously mill extremely complex geometries in 5 axes, build the model entirely within the center, and in some cases, produce multiple models simultaneously,” Nava continues.

The flexibility, autonomy, and reliability guaranteed by the first machining center were decisive in the choice to purchase a second Belotti milling machine.

“The reliability of the center allows us to operate remotely for machining processes that can exceed 24 hours without the operator being present at the machine, monitoring all processes through a camera system and ensuring high productivity even outside working hours,” says Nava.

The build quality and reliability of these machining centers are still confirmed today by minimal maintenance costs.

“The quality of Belotti centers has guaranteed us reliability and continuity. And when needed, technical assistance is fast and effective. It’s an aspect we’ve come to appreciate and that weighed heavily in the choice of a machine that is now the heart of our model-making business,” concludes Nava.

With this latest investment, FA.ST.MODEL reaffirms its commitment to technological innovation in thermoplastic polymer machining, enhancing production capacity and responding to the ever-evolving needs of its clients.

For more information on Belotti FLA machining centers, please refer to the dedicated “FLA Series” page