The thermoforming sector is one of the most served by Belotti since its foundation, as CNC machining centers are widely used for fast trimming and milling operations on thermoformed components.

Within its range of 5-axis cnc machining centers, Belotti TRIM and Belotti FLA Series are particularly suitable for high-speed trimming and milling operations on plastics and composites components previously subjected to thermoforming processes.

Both Series are now operating at Modula Industry srl plant, an Italian company part of the Epta Group and specialised in the production of plastic components for the industry. The company coordinates the entire production process – design, feasibility study, prototyping and production – of structural components and accessories for industrial vehicles, earthmoving machineries, utility and public transport vehicles, furniture and automotive sector in general.

All aesthetic and functional finishes on the components (e.g. ventilation slots, pre- and post-gluing dimensional adjustments, holes and housings for fastening components and accessories…) are performed by Belotti 5-axis CNC centers, able to carry out the most complex operations requiring high-levels of accuracy.

The first puchase of a Belotti FLA 4018 CB machining center is dated back to 2008, followed by a Belotti FLA 5526 center and a Belotti TRIM 4015 center in later years.

In 2022, the collaboration between Belotti and Modula Industry was further consolidated through the purchase of 3 new Belotti TRIM 4016 CB centers, equipped with a rotary table for loading and unloading operations.

“Belotti machining centers are now part of the history of Modula which, since the early years of its activity, has chosen them because of their exceptional performance, immediately establishing a relationship of collaboration and mutual trust that continues to this day“, declares Massimo Brugnettini, CEO of Modula Industry srl.

“Their high-speed and machining precision allow to carry out key cutting and drilling tasks even on extremely complex and detailed projects, guaranteeing absolute fidelity to the project and optimising all machining operations, in order to obtain a competitive and high-quality finished product, significantly reducing production times and thus increasing the company’s production efficiency”, continues Brugnettini.

The three Belotti TRIM 4016 centers are equipped with:

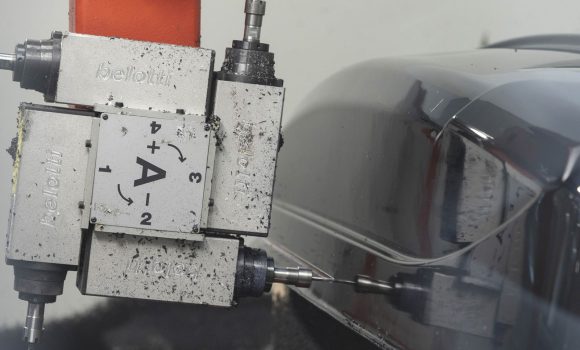

- 5-axis head with R4 (4 spindles) revolver with maximum rotation 24,000 rpm

- Perimeter enclosure

- Belotti MyB IoT Software

and they are all managed by Osai numerical control, which facilitates their management and use by operators.

The rotary system allows to optimise the loading and unloading operations of the thermoformed components, increasing the overall productivity.

The success of this multi-year collaboration between the two companies also lays on the quality of Belotti after-sales services, which support the customer during the entire life cycle of each machine.

“We have always been able to count on a precise, efficient and punctual customer service assistance, thanks to a Service Team constantly ready to cover the needs of a sector that requires constant technological updating and with the best tools available. For this reason, we are strogly committed to further improve this partnership, with the mutual goal of obtaining high-quality results and being able to satisfy the most complex needs of our customers“, concludes Massimo Brugnettini.

Find out more about Belotti’s cnc machining centers for thermoformed plastics milling.