NESTING Series

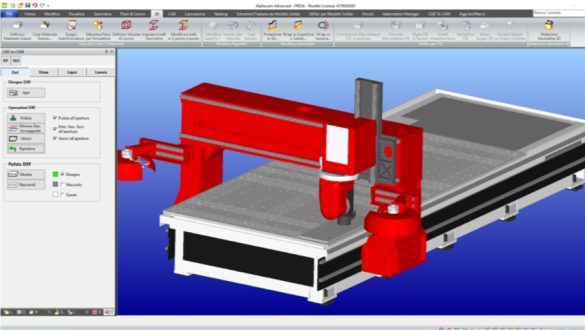

3-axis compact Series of cnc centers for machining large plates in aluminum and plastic materials.

The NESTING Series is Belotti’s compact and highly flexible technological solution, developed to meet the demands of multiple industrial sectors: packaging, mechanical industry, checking fixtures, automotive and aerospace.

It’s the ideal solution to machine and nest even small pieces out of large aluminum plates or technical plastic panels, up to 50 mm thick.

Description

The three-axis machining centers of the NESTING Series are characterized by a small footprint and machining efficiency indicators of 100% for plastics, 70% for aluminum and 30% for resins.

The minimum footprint configuration, combined with the high dynamism of the milling head, guarantee maximum quality of the machined surfaces and high productivity thanks to the optimization of the cycle-times and the material used.

The Belotti NESTING 3-axis centers are designed to operate in unattended mode during the entire cycle-time, allowing a significant reduction in operator-cost and a high return on investment (ROI).

The compact and monolithic structure, made up of electrowelded steel with double 90° slideways on both baseframe sides, grants a high rigidity of the bridge and a reduction in handling and installation times.

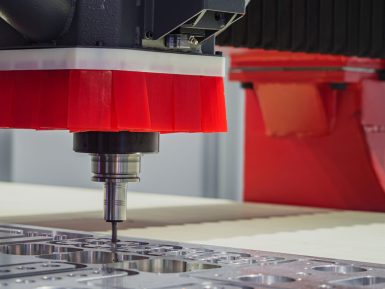

The aluminum suction table with MDF panel and vacuum locking system and the suction system with NC electronic adjustment of the hood, ensure a better cleaning and safety of the working environment.

The “Easy Programming” option, the CAM/CNC plug-in software developed by Belotti, simplifies the programming of 2D geometries nesting and complex machining operations, supporting the operator with machining center’s operation.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Packaging

- Checking fixtures

- Automotive

- Aerospace

- Railway

- Design and furniture

- Marine

- Energy and building

Materials

- Technical plastic

- Aluminium panels

- Light alloys

- Plastic

- Resins

Technical features

| Axis | X | Y | Z |

|---|---|---|---|

| Stroke | 3/4 m | 1,6/2/2,5 m | 0,45 m |

| Speed | 50 m/min | 30 m/min | |

| Spindle | From 15 kW up to 22 kW at 24.000 rpm max. | ||

| CNC | Fanuc, Siemens | ||

| Tool change | From 11 to 30 positions | ||

| Linear accuracy | ≤ 0,015 mm/m for linear axes | ||

Accessories

Aluminium vacuum table with MDF panel

Aluminium table on which MDF panels are screwed, especially designed for machining of aluminium plates.

The table is divided into 12 areas, with dimensions to be defined, that can be automatically managed by the CNC. It is equipped with vacuum electrovalves and preset vacuometers to check the minimum vacuum level on the part for safe clamping.

In case mechanical clamping is needed, the MDF panel can be removed.

Upon request, it will be possible to provide multiple rapid connections for vacuum clamping.

Electronic suction hood for 3-axis head

Scraps suction hood used with 3-axis machining, electronically controlled.

In a range of 180 mm the electronic hood automatically adjusts its extension according to the real distance from the part.

The hood automatically retracts during the tool changer.

The dust suction hood performance may vary according to the part geometry, to the material and to the machining strategy.

Vertical aluminium table

Especially recommended for machining on the side of the plate.

Positioned on the front of the table, it helps to centre and clamp the plates for milling, drilling and threading operations.

Minimal lubrication system through the spindle

Centralized grease system, complete with pressure control and minimum level in the tank, which provides for the automatic lubrication of the moving parts. Lubrication is managed by NC in fully automatic mode and allows an extension of the life of the mechanical parts.

Automatic tool changer up to 30 positions

Contact us for product information, technical support or spare parts requests.