25 septiembre 2025

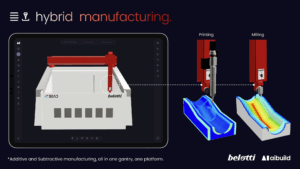

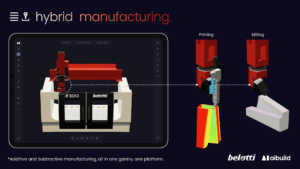

The new era of advanced hybrid manufacturing: Belotti BEAD now integrated into Aibuild software.

In today’s Large Format Additive Manufacturing (LFAM) landscape, the growing demand for complex components in high-performance sectors such as aerospace and motorsport has made hybrid manufacturing a delicate yet essential process. From prototype to production, manufacturers must balance high-speed output with pinpoint accuracy, while leveraging strategic material utilization and advanced process simulation to ensure flawless execution, enhanced efficiency, and reliable large-scale production.

All this—and much more— is now possible thanks to the integration of Belotti BEAD, the all-in-one gantry machine for large-format additive manufacturing and CNC milling, into Aibuild software, the platform enhancing the entire hybrid manufacturing process through a single user interface. Aibuild enables all components of additive manufacturing—hardware, software, and materials—to function as a unified, intelligent system, delivering unparalleled levels of automation and precision for Belotti BEAD processes.

Together with Aibuild, we have created two videos showcasing the simplicity and speed of programming applied to these high-performance industries, where lightweight materials, extreme precision, and optimized manufacturing workflows are essential.

Industry-specific features: aerospace applications

Aibuild software helps aerospace manufacturers achieve high-performance components and precision engineering through:

- Mould designer, automatically generating the stiffeners of the end tooling mould from a single surface, drastically reducing design time.

- Thermal simulation, ensuring consistent printing temperatures between layers to prevent build failures.

- Safety Check, preventing potential collisions and material limitations pre-production.

- Tool Changing, automatically switching between additive and subtractive processes to produce high-quality finished parts.

Tailored functionalities for motorsport component manufacturing

In addition to these features, Aibuild incorporates precision functionalities to ensure the production of lightweight and durable advanced components for the high-performance motorsport industry, including:

- Seam Alignment, improving surface quality by reducing defect accumulation during printing.

- Curvature Compensation, automatically adjusting the nozzle’s toolpath to precisely deposit the right amount of material and achieve sharp-cornered milled parts.

- Overhang Analysis, adapting layer thickness to prevent gaps and ensure structural integrity during printing.

Click on the video preview images for an in-depth look into this hybrid technology or visit Belotti BEAD page to learn more.